|

LOWER END

For Sportster & Buell

|

Quick Links:

|

General XL & Buell Crank Information

For 1991-up Sportsters and Buells

-

Why Do Harleys Vibrate So Much? There's a physics reason behind it. With pure rotating weight only (absent any reciprocating weight) a flywheel assembly could be balanced perfectly for all rpms, i.e.

it wouldn't matter how fast you spin it, it would always be in perfect balance. But connecting rods and pistons contribute reciprocating weight, and worse, the loads imparted onto the crank by

reciprocating weight go up as the square of the speed increase, rather than linearly. The classic way to balance when you have reciprocating weight is to design the motor such that the loads from one rod & piston

assembly offset the loads from another rod & piston assembly. However, the 45 degree common crankpin and knife & fork rod assembly make this impossible. So sans a counter balancer, we're

stuck with achieving proper balance at one rpm only, with vibrations increasing as the rpm is moved further and further away from that point. Therefore, the most effective thing you can do to improve the

balance on an HD motor is to minimize reciprocating weight, i.e. run lightweight connecting rods and pistons. Not only will this reduce vibration, but it will also reduce the wear and tear on the lower

end, make a failure less likely, and add power. At HAMMER PERFORMANCE, we offer

the lightest connecting rods and

pistons in the business for exactly this reason.

-

More Torque from Heavier Flywheels? No! This is bad information that even some professional shops spread around. Torque comes from cylinder pressure and it's mechanical advantage on the

crank (both bore and stroke give it mechanical advantage). The flywheel assembly simply stores the energy, it does not produce it. In fact, when you dyno test a bike on an acceleration

based dyno like a DynoJet, a bike with heavier flywheels will, all else being equal, show less torque and power than a bike with lighter flywheels! However, because heavier flywheels

store more energy, they make it easier to pull away at low throttle and low rpm without stalling, and likewise generally improve very low rpm manners.

-

883 or 1200? Through the 1994 model year, HD offered a separate crankshaft assembly for 883's and 1200's, each balanced for the appropriate pistons. However, beginning in 1995,

HD reverted to one part number for either model, a situation that remains true today. When buying a replacement 883 assembly for a 91-94, the part number now supersedes to the common assembly.

As explained above, the net result of this change is that the ideal rpm for minimum vibrations will be somewhat different between the two engine sizes, due to the difference in reciprocating

weight between 883 and 1200 pistons.

-

Buell or XL? 1995-1996 Buell S2 models used standard XL crankshaft assemblies. However, beginning with the S1 model introduced in 1996, and extending through the 2002 model which was the last year

of interchangeable Buell/Sportster cranks, Buells got lighter flywheel assemblies. The lighter flywheel assembly makes the bike rev quicker and will show more power on an acceleration based dynamometer

(e.g. DynoJet). The downside is slightly poorer low rpm manners. A lightweight flywheel assembly from a 1996-1999 Buell will go right into a Sportster from 1991-1999. Likewise a lightweight flywheel

assembly from a 2000-2002 Buell will go right into a 2000-2003 Sportster. Beginning with the Buell XB model introduced in 2003, there is no more interchangeability between Sportster and Buell cranks.

Likewise, the 2004 & newer XL cranks (rubber mounts) do not interchange with earlier XL cranks. However, HAMMER PERFORMANCE offers a service to allow the latest 1.5" crankpin Buell XB and XR1200 Sportster

crank to 91-03 XL's and 95-02 Buells, see below for details.

-

Pressed or Bolted? Beginning in 2000 all factory XL & Buell cranks became press together assemblies, as opposed to the bolt-together versions found on 1991-1999 models. The press together style cranks greatly

complicate crank servicing, in fact HD stopped selling service parts for them, they only offer complete assemblies. However, the pressed design does add some rigidity to the whole assembly and they have proven

reliable in street performance applications. Fitted with quality connecting rods, trued, balanced,

and welded, they've proven suitable for race applications as well. Press-together cranks from 2000-2002 Buells and 2000-2003 Sportsters can be fitted to 91-99 motors with a minor machining operation

on the right side case half, which HAMMER PERFORMANCE can provide for you. Bolt together cranks from 1991-1999 models can be fitted to 2000-2002 Buells and 2000-2003 Sportsters with no problem.

-

What's the Best Crank? Starting in 2008, all Buell cranks got a new 1.5" crankpin, as did the XR1200 model. All other XL and Buell cranks came with a 1.25" crankpin. The larger 1.5" piece greatly increases the rigidity of

the crank, resisting "spread" which can cause pinion runout and breakage. These cranks are a bolt-in replacement for 2004+ XL and 2003-2007 Buell XB models, if you buy the alternator/rotor assembly and the bolt and washer

as well. They can be fitted to 91-03 XL's and 95-02 Buells with a special machining service offered by HAMMER PERFORMANCE, see below.

|

XR/XB Crank Conversion

For 1991-2003 Sportsters and 1995-2002 Buells

In 2008, HD came out with a massively improved crankshaft assembly for Buell XB and

Sportster XR1200 models. This assembly features a large 1.5 inch crankpin to resist spread and eliminate big end bearing

issues, as well as a large splined sprocket shaft for more strength and connecting rods made of a stronger material. It's also about 3lbs lighter than a stock 2004+ XL crank.

It's essentially a racing grade crank but at a fraction of the price of competitive aftermarket

offerings. It bolts right into 2004+ XL's and 2003-2007 Buell XB's if you also get the new matching front primary sprocket/rotor (available in 34T or 38T) as well as the bolt and washer that hold it on.

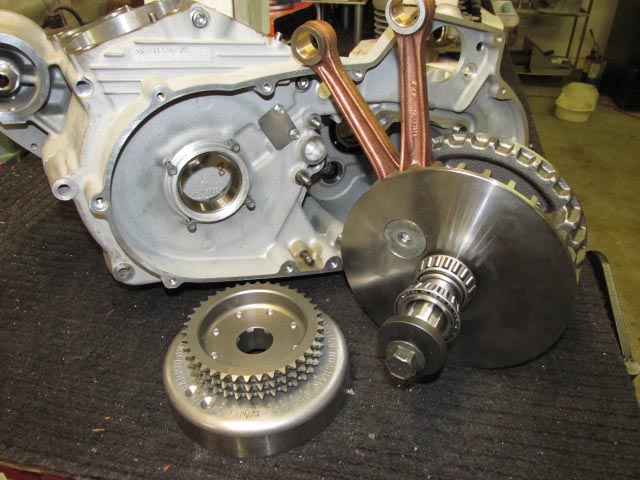

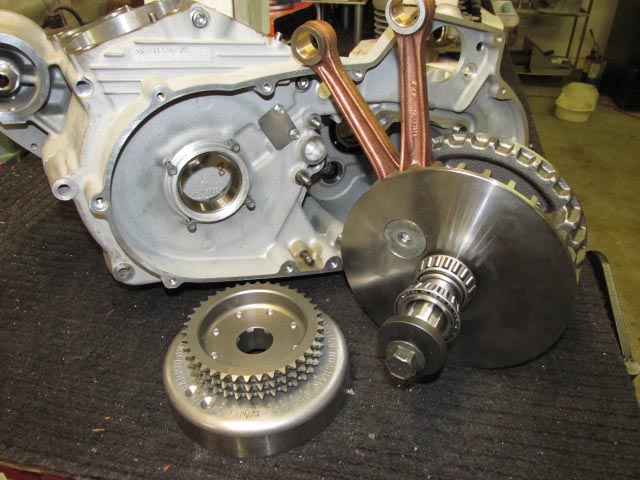

91-03 style Sportster cases machined to accept the XB/XR1200 flywheel assembly shown

This crank is so desirable that in the spring of 2014, HAMMER PERFORMANCE set out to fit it to the 91-03 series of bikes, which are much preferred among racers. We succeeded in doing so and since

then we've fitted this crank into numerous lower ends destined for high performance street and race applications, and the modification has proven successful. If

your 1991-2003 XL or 1995-2002 Buell is in need of crank work, you should seriously consider this upgrade. It's a far superior crank to your other alternatives and

the price is reasonable

CNC machining the left case half to accept the XB/XR1200 crankshaft

The flywheel assembly, rotor/sprocket assembly, retaining bolt & washer, machine work, and special parts needed to use this crank are bundled with the complete

overhaul of the bottom end, including new sprocket shaft bearings and races, a new outer pinion race pressed into

the right case half and line-lapped to the sprocket shaft side, a new pinion bearing, installation of the flywheel assembly and setting the flywheel end play,

a new sprocket shaft seal, and complete assembly of the lower end. In other words, it comes back to you completely rebuilt and ready to have you finish the engine assembly

and install it in the bike. Please click here for a detailed quote of the parts and services provided in this bundle.

Note: this crankshaft has been discontinued by HD. We can still perform the service if you can supply the crank and front primary sprocket, bolt, and washer.

|

Crank Work

HAMMER PERFORMANCE can handle all your Sportster/Buell crank prep!

A pressed crankshaft for a rubber mount XL Sportster with Carrillo rods and welded crankpin

At HAMMER PERFORMANCE, we have extensive experience preparing crankshafts for high performance and racing use. We know what works and what doesn't, and we know all the little tricks to make them

as durable as possible. See below for a selection of the services we offer. These prices are for the service work only, parts are additional. See below for our selection of lower end hard parts.

Crankshaft Services for Sportsters & Buells |

Service |

Purchase |

Service XL Crank

Disassembly, Replace Worn Parts,

Reassemble, True

Balance Optional

Note: pressed together cranks serviced in

partnership with Dark Horse Crank Works |

Contact Us

|

Weld Crank Assembly

Adds Rigidity and Strength |

Contact Us

|

Cryo Treat Crank Assembly

Improves Durability Under Severe Conditions |

Contact Us

|

Resize Rods

For Rods with Out of Round Big Ends |

Contact Us

|

Weight Redistribution

Helps Resist Flywheel Spread in High Rpm Applications

Requires Rebalancing |

Contact Us

|

|

Connecting Rods

Quality Connecting Rods from Carrillo

One of the first lower end components you should consider upgrading on your XL or Buell hot street or race motor is the connecting rods. A connecting rod

failure is an ugly thing that ultimately costs much more than it costs to just get a good set of rods in the first place.

At HAMMER PERFORMANCE, we've used all of the popular XL connecting rods, and one brand stands out for their superb quality, high strength, and light weight: Carrillo.

These rods have endured brutal beatings at the hands of our 200+mph nitro burning Bonneville Sportster. They will easily hold up in your street or race motor.

In addition to being enormously strong, these rods are also very light, lighter even than the stock pieces, which is remarkable considering how much stronger they are.

Less reciprocating weight means less vibration, less wear and tear on the lower end, and more power. They're a terrific complement to our

ultra light weight Sledge Hammer pistons.

Carrillo rods are made from their proprietary alloy forgings. They're currently only offering XL rods in one size off-the-shelf, a 6.938"

length with a 1.25" crankpin. The 6.938" length is .012" longer than stock to give a little tighter squish with typical gaskets.

If you require a different length and/or a different crankpin diameter, give us a call. Carrillo will do customs. Call to discuss your needs and we'll get you a quote.

Carrillo Rods for Sportsters and Buells |

Application |

Length |

Big End I.D. |

Crankpin |

Purchase |

83-Present XL, 95-07 Buell (except Blast, XB9, 1125) |

6.938" |

1.625" |

1.25" |

|

Custom |

Custom |

Custom |

Custom |

Please Call |

|

Lower End Parts

Bearings and Other Hard Parts for your Sportster/Buell Lower End

At HAMMER PERFORMANCE, we can supply all of the hard parts it takes to put a lower end together. We build these motors all the time and we almost always have the parts in stock.

If you don't see what you need listed, give us a call, chances are we have it on the shelf.

Lower End Hard Parts for Sportsters and Buells |

Description |

Purchase |

Pinion Shaft Bearing

Note: Select bearing color code based

on table in factory service manual |

|

Sprocket Shaft Bearing Set

Matched set with bearings, races,

shim, and spacer |

$95.95

|

Sprocket Shaft Bearing Shim

Note: Select shim size for .001 to .005

flywheel end play |

|

Rod Bearing Cages (set)

Aluminum cages hold 17 rollers each

These cages require the use of non-stepped

copper thrust washers below |

$36.95

|

Rod Bearing Roller Set, 34 rear + 17 front |

|

Big End Thrust Washers (not shown)

Note: be SURE to match the thrust washer

type to the height of the cages

Sold in pairs |

|

|

|

|

|

|

|

|