Sledge - $1200:

Hit it as Hard as You Can, Use a Sledge!

For your maximum-effort engine, we offer the Sledge Hammer service.

The Sledge service builds on the Smash service, including all of the high-tech preparation and premium

componentry. But what if your application needs even bigger valves, that require a seat change? What if you want

to use an angle dome piston? Or install compression releases? Or dual plug your heads?

Sure, you can add those services (and others) to your Smash heads ala carte. But the Sledge service includes any or all

of these extras for no extra charge, saving you money!

But the real advantage to the Sledge level is a whole different, exclusive porting process. You see, CNC is a great way

to port heads. It results in far more repeatability and consistency than is possible with a human using a die grinder. But

it's big strength is also it's big weakness; every port comes out the same.

So what do you do when the size of your motor, and the way you have it cammed, and the way you intend to run it, is not a perfect

match for the CNC port profile? Well, until now your choices were to get a hand porting job (and hope that the person with the die grinder

does it well matched to your application, which is a big "if"), or live with a one-size-fits-all CNC porting job.

At Hammer Performance, these choices weren't good enough. We set out to solve the problem, and spent years and countless man-hours developing

and refining the ultimate solution:

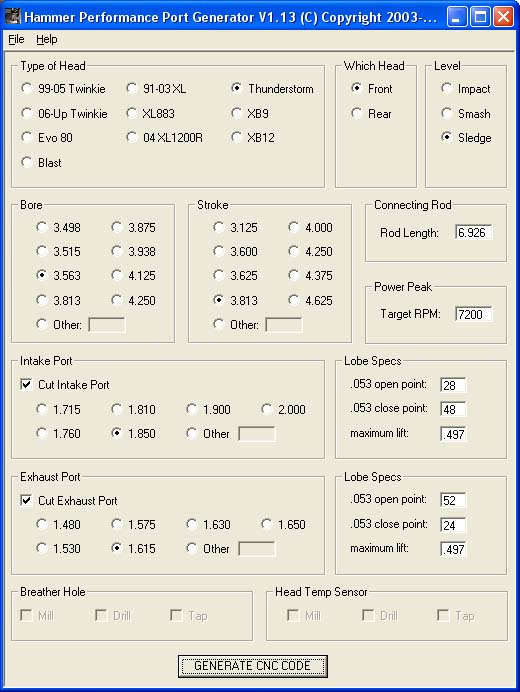

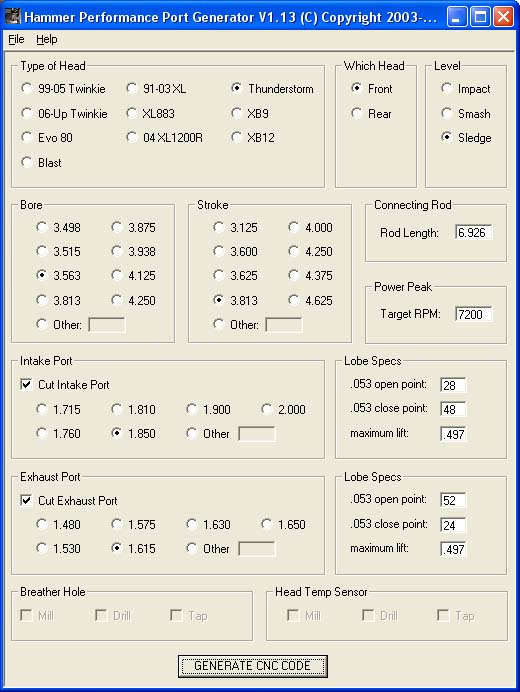

Screen Shot of the Hammer Performance Port Generating program, set for SLEDGE mode

As you can see, our port generating program, when set for Sledge heads, allows key engine parameters as

well as target rpm to be input. Based on these numbers, the program calculates the ideal port cross sectional area

for the application and generates a CNC program, on the fly, to perfectly match.

This program was developed in-house, and nobody else has anything like it. If you want the advantages of CNC, but still want your

heads custom-fit to your application like a fine Italian suit, Hammer Performance has the answer!

This process has been in place and continually refined since 2003, and it's been used on literally thousands of heads since then. The

results have been stunning, from the hundreds of satisfied street riders to the numerous records broken at the Bonneville Salt Flats. Here's an

example of what the SLEDGE service can do:

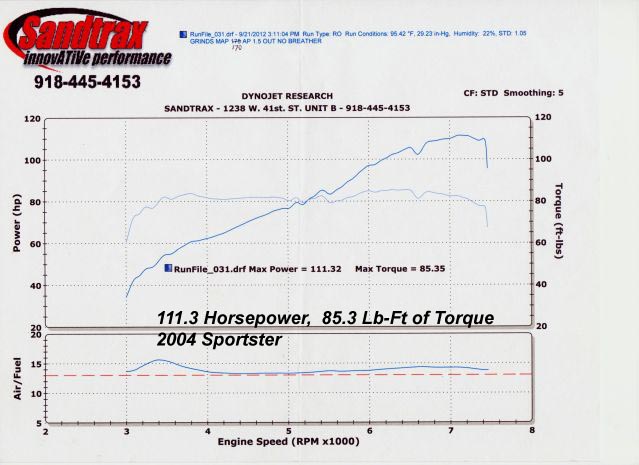

This dyno sheet is from a 2007 XL883 Sportster, with three different flavors of our SLEDGE service. It's equipped with a 30 degree

1250 kit, a set of our

CRUSH 600 cams,

Air Hammer Air Cleaner (SLEDGE model),

Dynojet Powervision,

and a

Patriot Defender Exhaust.

In blue is the result with EFI 1200 heads that received some special welding in the intake port ("SLEDGE PLUS" service) as well as an HPI 55mm throttle body.

Red shows the same bike with a set of our standard SLEDGE ported EFI 1200 heads and a ported version of the factory throttle body & manifold.

And finally, green shows the the same as red except we applied the SLEDGE service to a set of 883 heads instead.

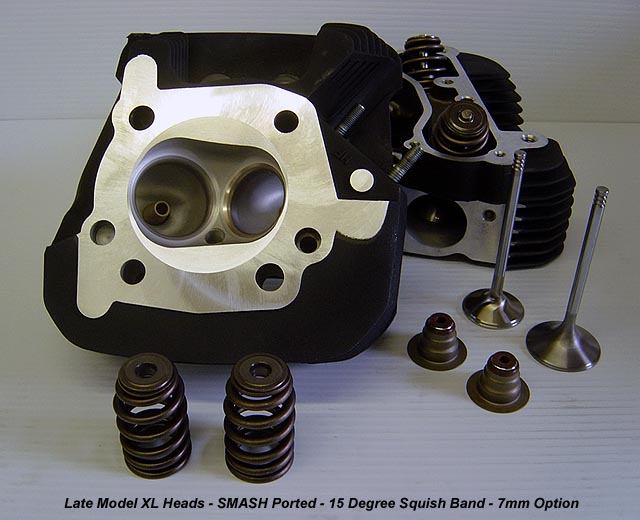

The Sledge includes even bigger oversized high flow stainless steel valves than the Smash level (up to 2.000" is

possible for certain XL heads) and a spring pack matched specifically to your application (up to .800" lift!).

A top shelf spring pack with Titanium retainers is standard at the Sledge level.

Head work is sold by quotation only. Please Contact Us for more information.

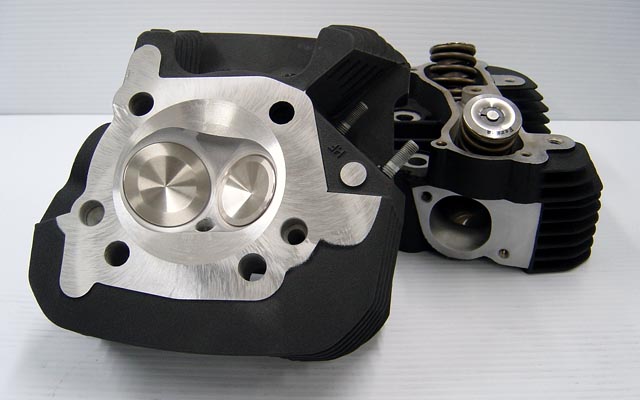

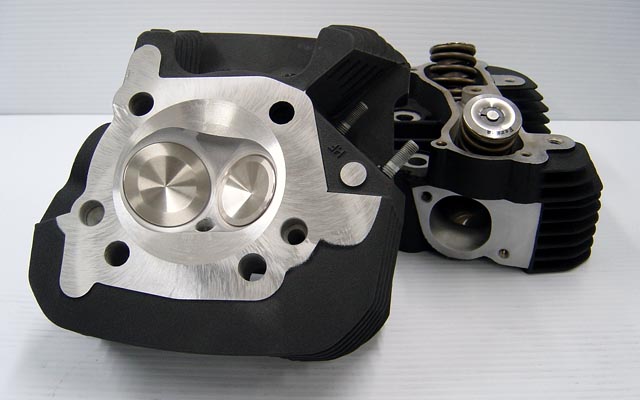

A set of SLEDGE prepared Buell XB heads set up for an 88ci motor

|

set of heads at reasonable cost. If you have a set of Thunderstorm, XB, or 2004-present XL1200 heads, and you're going to be using cams of above .550 lift, you can take advantage of this special service.

set of heads at reasonable cost. If you have a set of Thunderstorm, XB, or 2004-present XL1200 heads, and you're going to be using cams of above .550 lift, you can take advantage of this special service.